Environmental Protection Acceptance Opinions on Completion of Construction Project of Overall Relocation of Pigment Production Equipment of Penglai Xinguang Pigment Chemical Co., Ltd.

Release time:

2023-02-14

Penglai Xinguang Pigment Chemical Co., Ltd.

Pigment production device overall relocation construction project completed

Comments on acceptance of environmental protection

Penglai Xinguang Pigment Chemical Co., Ltd.

2017Year12Month19No.

Penglai Xinguang Pigment Chemical Co., Ltd.

Comments on Environmental Protection Acceptance of Completion of Construction Project for Overall Relocation of Pigment Production Equipment

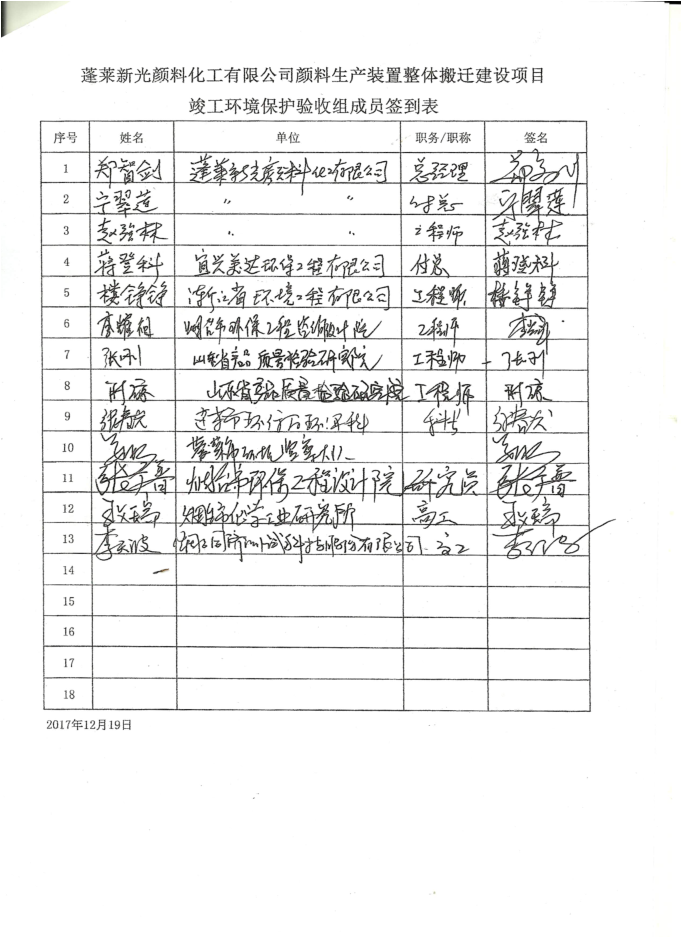

On December 19, 2017, Penglai Xinguang Pigment Chemical Co., Ltd. organized relevant personnel to set up an acceptance working group to conduct on-site environmental protection acceptance for the overall relocation of the pigment production equipment of Penglai Xinguang Pigment Chemical Co., Ltd, the meeting was attended by Penglai Environmental Protection Bureau, Beigou Squadron of Penglai Environmental Supervision Brigade, design unit Zhejiang Environmental Engineering Co., Ltd., construction unit Yixing Meida Environmental Protection Engineering Co., Ltd., supervision unit Yantai Environmental Protection Engineering Consulting and Design Institute, acceptance monitoring unit Shandong Product quality Inspection and Research Institute, and three technical experts were specially invited at the meeting (the list is attached). The acceptance working group listened to the construction unit's project and environmental protection implementation, the environmental supervision unit Yantai Environmental Protection Engineering Consulting and Design Institute, and the acceptance monitoring unit Shandong Product Quality Inspection and Research Institute's completion environmental protection acceptance monitoring report, and inspected the project on site And the construction and operation of environmental protection facilities, reviewed and verified relevant information. After careful discussion, the acceptance advice is formed as follows:

Basic situation of 1. engineering construction

The original site of Penglai Xinguang Pigment Chemical Co., Ltd. is located in Chengdong Shahe Road, Penglai City.On the 7th, due to the change of planning in early 2011, the company needed to move to the chemical industry park of Beigou town in Penglai city as a whole. The company conducted an environmental impact assessment on the relocation project in May 2011, and passed the approval of Yantai Environmental Protection Bureau on August 30, 2011 (approval document number: Yan Huan Shen [2011] No. 102). The construction of this project started in February 2012. During the construction process, the land occupation, sewage treatment process, pollutant discharge, main raw and auxiliary materials, products and output of the project have changed. According to the "Reply of Yantai Environmental Protection Bureau on the Changes of the Construction Project of Penglai Xinguang Pigment Chemical Co., Ltd. Relocation Chemical Park" (Yan EIA Letter [2015] No. 72), the construction unit commissioned Yantai Environmental Protection Science Research Institute to re-compile the EIA report in 2016, and Yantai Environmental Protection Bureau approved the project with Yan Huan Shen [2016] No. 16 on January 18, 2016.

The project is constructed in stages, and this acceptance is the first phase of acceptance. The products of this period include: organic red pigment2600t/a, organic yellow pigment 3041t/a, Hua Lan pigment 3000t/a. The existing project was started in February 2012 and completed in December 2016. The actual total investment is 250 million yuan, of which the environmental protection investment is 40 million yuan.

Changes in 2. works

This acceptance is for smoke ring review.[2016] No. 16 approval of the first phase of the project content, the heat-conducting oil furnace using coal to change to biomass pellet molding fuel, the acceptance team believes that the project has not undergone major changes.

Implementation of 3. environmental protection facilities

Dust generated in the production process of the project38 bagging devices for processing.

The acid mist enters the spray washing tower for treatment. The breathing valve of ammonia water is connected with the water spray tower, and the waste gas generated during the unloading of ammonia water enters the water spray treatment.

The project wastewater includes production wastewater, laboratory wastewater, reverse osmosis high-salt wastewater, ground flushing wastewater and domestic sewage, all of which are discharged into the sewage treatment station (daily treatment capacity7500 tons/day, high ammonia nitrogen wastewater is treated by ultrasonic denitrification, high concentration wastewater neutralization and precipitation, and then mixed with low concentration wastewater for hydrolysis acidification contact oxidation treatment, and then discharged into Beigou Town Comprehensive Sewage Treatment Plant for further treatment.

Noise reduction measures such as noise elimination and sound insulation are taken for the main noise sources.

Solid waste is properly disposed.

An emergency plan for environmental risks has been formulated and environmental risk prevention measures have been implemented.

The company has an environmental protection management organization, and the environmental protection rules and regulations are relatively perfect.

Commissioning effect of 4. environmental protection facilities

1. Exhaust gas

During the acceptance monitoring period, the particulate emissions of each crushing and drying exhaust cylinder of the project meet the "Shandong Province Regional Comprehensive Emission Standard of Air Pollutants".DB37/ 2376-2013 Table 2 Standard, and EIA Approval Standard (Shandong Province Comprehensive Emission Standard for Atmospheric Particulate Matter from Fixed Sources "DB37/1996-2011 (abolished). The sulfuric acid mist in the acid mist spray tower of Hualan workshop meets the requirements in Table 2 of the Comprehensive Emission Standard of Air Pollutants. The hydrogen chloride concentration in the acid mist spray tower on the east side and the hydrogen chloride concentration in the acid mist spray tower on the west side of the azo workshop meets the requirements in Table 2 of the Comprehensive Emission Standard of Air Pollutants. The concentration of ammonia in the denitrification exhaust cylinder of the sewage station, ammonia and hydrogen sulfide in the odor scrubber of the sewage station shall meet the requirements of Table 2 of the Emission Standard for Odor Pollutants (GB14554-93). Sulfur dioxide, nitrogen oxide particulate matter, mercury and their compounds in heat-conducting oil furnaces meet the regional comprehensive emission standard for air pollutants in Shandong province DB37/ 2376-2013 table 2, and mercury and its compounds meet the second-class coal-fired boiler standards in the second-class zone in the second-class period of the GB13271-2014 "comprehensive emission standard for air pollutants from boilers" table 2. Ferrous sulfate dissolved acid mist spray tower sulfuric acid mist meets the requirements of Table 2 of the Integrated Emission Standard of Air Pollutants.

During the monitoring period, the concentration of unorganized waste gas, particulate matter, ammonia, hydrogen sulfide, odor, sulfuric acid mist, hydrogen chloride, nitrogen oxides, acetic acid and aniline meet the requirements of the Integrated Emission Standard of Air Pollutants.2 It is required that the concentrations of ammonia, hydrogen sulfide and odor meet the factory boundary standard value of odor pollutants in Table 1 of the Emission Standard for Odor Pollutants (GB14554-93), and acetic acid meets the estimated value. Canteen oil fume is discharged after being treated by oil fume purifier, and the emission concentration meets the emission standard of oil fume in catering industry (DB37/597-2006).

2. Waste water

Outlet water quality of sewage station during acceptance monitoringThe pH value is between 7.48 and 7.64, and the daily average concentrations of COD, BOD ammonia nitrogen, suspended solids, chroma, total nitrogen and total phosphorus meet the B grade standard in Table 1 of "Water Quality Standard for Sewage Discharged into Urban Sewers" (GB/T31962-2015) and the B grade standard in the approved standard "Water Quality Standard for Sewage Discharged into Urban Sewers" (CJ343-2010).

3. Noise

Acceptance monitoring periodThe maximum daytime noise of each plant boundary is the west point of the north plant boundary, with a noise value of 67dB(A), and the maximum night noise is also the west point of the north plant boundary, with a noise value of 59dB(A). The noise of other plant boundaries during day and night is up to standard. There are no sensitive points within 200 meters around the project, and the impact of excessive noise is not significant.

4. Solid waste:

The solid wastes of the Project mainly include waste packaging materials, waste permeable membrane, boiler ash, sewage station sludge and domestic garbage. Waste packaging materials and waste permeable film manufacturers recycle, boiler ash is collected and composted as agricultural fertilizer, sewage station sludge is entrusted to Yantai Xinguang Green Ring Renewable Resources Co., Ltd. for disposal, and domestic waste is cleared and transported by sanitation.

The plant will build a hazardous waste repository in the sewage treatment area, with an area120m2,Local anti-seepage treatment can meet the requirements of hazardous waste storage.

5. Environmental risk prevention facilities and emergency measures

Seepage control measures have been taken on the ground of the project workshop, hazardous waste temporary storage room, sewage pool, accident pool and tank farm.

The plant is equipped with an accident pool and an initial rainwater collection pool, and the rainwater drainage pipe is equipped with a control valve.

The company has formulated the environmental risk emergency plan and filed it with the environmental protection department, with the record number:30684-2017-0042-L。

The health protection distance of the project is100m, no environmental sensitive protection target within the health protection distance.

6. Total amount control

Project sulfur dioxide, nitrogen oxides,The total amount of COD and ammonia nitrogen meet the requirements of the confirmation of the total amount of pollutants of the construction project in Yantai City.

Impact of 5. engineering construction on the environment

The environmental quality of the surrounding sensitive targets is not required in the EIA and approval documents of the Project. in public opinion surveys100 per cent of the respondents were satisfied or basically satisfied with the environmental protection work of the project.

6. acceptance conclusion

Penglai Xinguang Pigment Chemical Co., Ltd. has complete insurance procedures for the overall relocation of pigment production equipment, and has implemented various environmental protection requirements in the EIA document and approval. During the trial operation, pollutants are basically discharged up to the standard, and the main pollutants meet the requirements of the total amount control index., the project has the acceptance conditions, the project environmental protection facilities acceptance.

7. follow-up requirements

1, pigment drying facilities outlet should be closed measures to reduce unorganized emissions;

2, according to the management requirements of self-monitoring, the implementation of environmental monitoring plan requirements;

3. Strengthen the daily maintenance and management of various environmental protection facilities, strengthen on-the-job training, establish and improve the operation account of environmental protection facilities, and ensure the normal operation of environmental protection facilities and the stable discharge of various pollutants up to the standard;

4. This environmental protection acceptance is phased acceptance, and the project should apply for overall environmental protection acceptance after reaching the design capacity.

Acceptance Team

2017.12.19

Recommended News

Q2 2024 Exhaust Gas Testing Report

2024-07-17

Q1 2024 Exhaust Gas Testing Report

2024-07-17

Address: No. 3, Hai Run South Road, Bei Gou Industrial Park, Peng Lai City, Shan Dong Province, China PRC

Telephone: 0086-535-3459277 / 3455799

Fax: 0086-535-3459236

Phone: 086-15910026590

Email: william@plxingguang.com

SAF Coolest v1.3.1.1 设置面板 FEESX-AGNG-PAAZE-ZVX

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page